- Analytics & Modeling - Predictive Analytics

- Healthcare & Hospitals

- Maintenance

- Predictive Maintenance

- Data Science Services

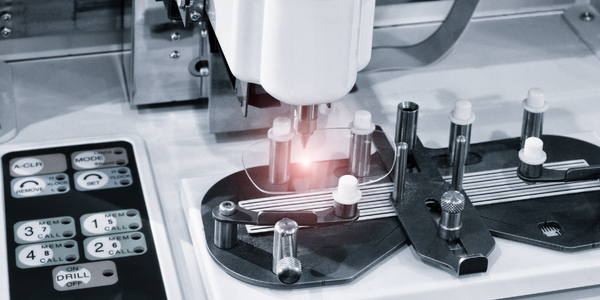

Seeing that one of their goals is to find ways to better answer consumer and business needs, the Global Engineering (GE) team was facing the challenge of improving processes and performance of the surfacing machines to significantly improve their production by using the increasing volume of data.

"We wanted a data science platform that would allow us to solve our business use cases very quickly. Thanks to Dataiku and its collaborative platform, which is agile and flexible, data science has become the norm and is now used more widely within our organization and around the world," said Cédric Sileo, Data Science Leader at Global Engineering, Essilor.

The GE team at Essilor was able to use Dataiku for a predictive maintenance use case. The goal was to be able to indicate to operators the right time to change the consumable components so as to optimize their lifespan, while also guaranteeing the production quality standards.

In addition to using Dataiku to predict the optimal conditions under which they will use the consumables completely, the GE team also leverages Dataiku’s web application feature to provide a visual decision tool to help operators make a consistent choice when they have to change the consumables.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.