- Functional Applications - Remote Monitoring & Control Systems

- Sensors - Air Pollution Sensors

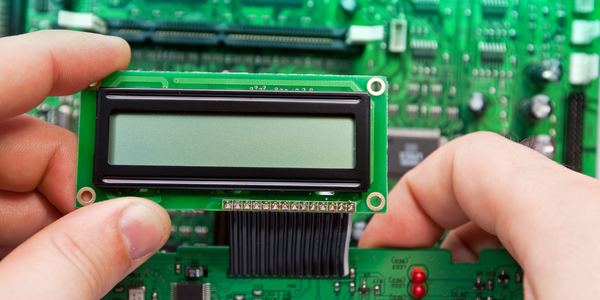

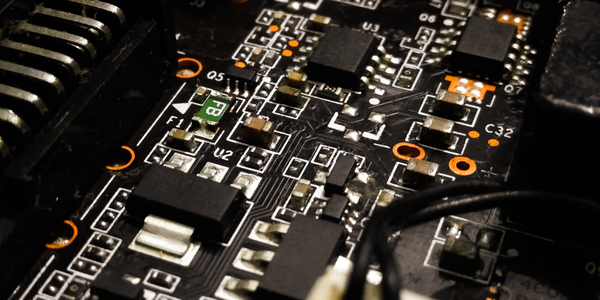

- Electronics

- Business Operation

- Indoor Air Quality Monitoring

Semiconductor production environments are “clean rooms” and must be tightly monitored in order to reduce the possibility of product contamination. A dusty environment will almost certainly lead to quality control issues. In order to prevent such disasters, STMicroelectronics installed a data monitoring and centralization system that instantly recognizes a problem and alerts the appropriate people.

In order to prevent such disasters, STMicroelectronics installed a data monitoring and centralization system that instantly recognizes a problem and alerts the appropriate people. This system was supplied by WIN-911’s European partner, Micromedia International. STMicroelectronics uses Micromedia’s ALERT alarm notification software to supervise the facility’s environmental conditions and promptly notify operators should any problems arise. STMicroelectronics uses the InTouch supervisory system to monitor the facility, and ALERT Software is set up alongside for alarm implementation. If any equipment stops, critical levels are reached, quality parameters are at stake, and/or a machine encounters a defect, the InTouch supervisory system will detect it and ALERT will deliver the message.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.