- Networks & Connectivity - RFID

- Sensors - RFID Readers

- Wearables - Tags & Patches

- Apparel

- Logistics & Transportation

- Track & Trace of Assets

Patrizia Pepe wished to improve the logistics of their warehouse: accepting incoming goods from their production sites, movement of items throughoutŌĆ©the warehouse, and packaging of goods for distribution to the retail locations. They initially tried to use barcodes for this function. Because barcodes must be individually scanned within a line-of-sight, the acceptance of goods coming into the warehouse was too time consuming. Working with the University of Florence, Patrizia Pepe instituted a five-month pilot project beginning in August of 2009 to test the validity of an RFID solution. The pilot involved tagging of about 60,000 items for the second seasonal collection, and convinced the company to move forward with tagging all items.

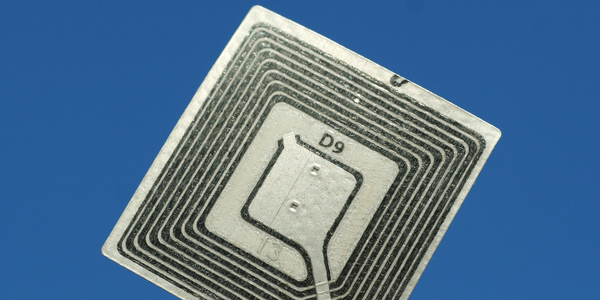

Patrizia Pepe selected Solos Identificazione e Protezione as the system integrator ŌĆ©for the production project. Solos, being more focused on item and identification and labels rather than the hardware, contracted with The Red Tree for the RFID hardware. The Red Tree, in turn, selected the Impinj Speedway Revolution reader because of its reputation for high quality and excellent performance. Initial work during the pilot phase included choosing where to locate the RFID tag,ŌĆ© as well as what information to write. In Patrizia Pepe’s case, they decided to include the EAN 13 (a barcode standard that originated in Europe, but is defined by GS1 standards organization as a superset of the United States Universal Product Code), country of production information, and the production order. They located the RFID tag behind the barcode on their brand label, so they could encode the RFID tag information simultaneously with the barcode printing. Currently, they use two types of label, a 64 x 34 cm and a 37 x 14 cm format. Both of these use Impinj Monza tag chips. Pre-encoded and printed tags are sent to Patrizia Pepe’s product manufacturers, who place the tags on finished goods. The problem then became one of ensuring valid reads of all the tags at the warehouse. For goods entering and exiting the warehouse in boxes, The Red Tree created custom tunnels to meet specificŌĆ©carton dimensional requirements.ŌĆ©Each custom tunnel includes four The Red Tree-designed antennas that connect to one Impinj Speedway Revolution reader. Patrizia Pepe uses seven of these tunnels, which also include a weighing system to verify the weight of each box passing through the tunnel. For apparel that travels throughout the warehouse on hanging-rack conveyors, The Red Tree created custom portals (also based on an Impinj Speedway Revolution reader) with four antennas—two near field and two far field. Four of these portals are distributed throughout the warehouse, allowing Patrizia Pepe to more easily pinpoint the location of goods within their operation.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.