- Infrastructure as a Service (IaaS) - Cloud Middleware & Microservices

- Equipment & Machinery

- Discrete Manufacturing

- Construction Site Monitoring

- Cloud Planning, Design & Implementation Services

| Background

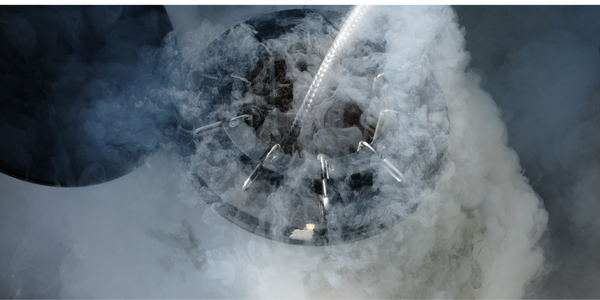

This customer is specialized in the development of ultra clean gas filling system technology for semiconductor wafer manufacturing. They require monitoring system to control the nitrogen pressure level of the FOUP machine. Their current system configuration is complicated to setup as it requires IP setting to connect FOUP serial server devices, which needs additional personnel to constantly monitoring the system. They are seeking for new system design to help improve the overall manufacturing facility efficiency, and pursuing higher product quality control.

| Challenges We Are Facing

- IP configuration and management of multiple connections

- High cost of deployment and maintenance

- Complete system shutdown for maintenance will affect production output

| Fast Deployment – Remote Monitoring Solution

With our SUNIX DevicePort serial expansion box, after simple driver installation, DevicePort are automatically paired and “Plug-N-Play” installed within 15 seconds. It eliminates complicated IP configuration setup and management; a big difference from other products in the market, and resolving high maintenance cost issue. In addition, status data from the machine will transmit through standard ethernet network to computers for monitoring at a remote location. It can eliminate the need for onsite personnel to monitor gas pressure level. Our DevicePort solution help improve the overall manufacturing efficiency and achieves quick project implementation and easy remote monitoring after deployment.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.