- Platform as a Service (PaaS) - Data Management Platforms

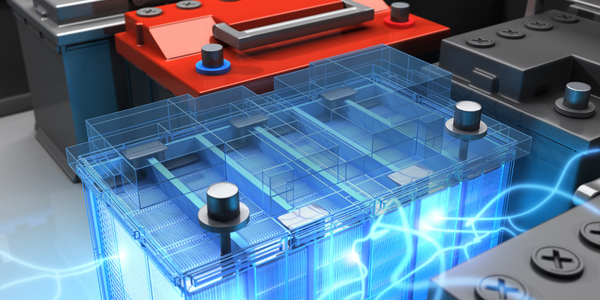

- Battery

- Field Services

- Machine Condition Monitoring

IOTATOI is a division of Power Agent Systems that has developed an edge server called the Universal Monitoring System (UMS). IOTATOI is using UMS as an edge tier data collector to monitor backup battery arrays in manufacturing, mines, and chemical plants. This experience with battery backups led IOTATOI to expand the system to any condition that can be monitored by sensors such as vibration, heat, temperature, and flow. IOTATOI found they needed to move from their original middleware to something that would allow greater scalability and to also present information in a much broader way allowing them to dynamically look at the information and perform benchmarking analysis, feeding the data into analytics engines and creating a much more actionable view.

IOTATOI had developed the physical ability to connect all of the sensors and bring it into a centralized location. Thingworx gave us the ability to seamlessly scale that information, view the information from any location, push information to any location, and do some unique things that they were unable to do with their existing middleware. The addition of ThingWorx to the UMS means that IOTATOI can have customers request a specific representation or report with the exact sensors they require. IOTATOI can create the mashup, set the sensors, configure where the data is to be sent, and enable it all with everything pre-configured when shipped. The customer then deploys the box on their site; calls IOTATOI to verify the solution is operating as configured and they can then be monitoring 5, 10, 15, 20 or more sensors on their equipment all at a fraction of the historical cost. To get a free demo of ThingWorx 8: http://solutions.iotone.com/thingworx

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.